The printing process used in laminate flooring is a critical factor in achieving the realistic appearance of wood, stone, tile, or other desired patterns. This process allows manufacturers to create a high-resolution image layer that mimics the natural material’s look and texture. Here’s an overview of how the printing process works for laminate flooring:

- Digital Imaging: The process begins with creating a high-quality digital image of the desired pattern, such as wood grain, stone texture, or tile design. This image is typically captured using high-resolution photography or digital scanning techniques.

- Inkjet Printing: Most modern laminate flooring manufacturers use inkjet printing technology to apply the decorative layer onto the core layer of the flooring. This technology allows for precise and detailed printing, resulting in a realistic appearance. Inkjet printing also offers versatility, as it can replicate various patterns, colors, and textures.

- Ink Application: Special inks designed for durability and resistance are used in the printing process. These inks are applied to the core layer in a controlled manner to accurately reproduce the image’s details, color variations, and textures.

- Multiple Layers: The inkjet printing process typically involves applying multiple layers of ink to the core layer. These layers create depth and variation, similar to how real wood or stone might have natural color and texture differences.

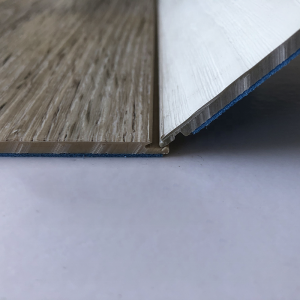

- Top-Coating: Once the ink layers have been applied, a protective top-coating is added over the decorative layer. This top-coating is usually made of melamine or another durable material. It helps protect the image from scratches, wear, and fading due to sunlight exposure. The top-coating also enhances the floor’s overall durability and longevity.

- Embossing (Optional): Some laminate flooring products undergo an additional embossing process after the printing and coating stages. Embossing involves pressing the surface with textured plates or rollers that mimic the natural texture of the material being replicated, such as wood grain or stone texture. This step adds a tactile element, enhancing the realism of the flooring.

The combination of high-resolution digital imaging, advanced inkjet printing technology, and protective top-coating allows manufacturers to create laminate flooring with impressive realism. The end result is a product that closely resembles the appearance of natural materials like wood, stone, or tile while offering the durability and affordability that laminate flooring is known for.

When choosing laminate flooring, it’s a good idea to review product samples or images to assess the quality of the printing and how well it matches your desired aesthetic. Reputable manufacturers invest in advanced printing techniques to provide a visually appealing and long-lasting flooring solution.